How to make large diameter stainless steel welded pipe stronger and more durable?

Posted by: Hangao Time:2024-2-21 8:48:04

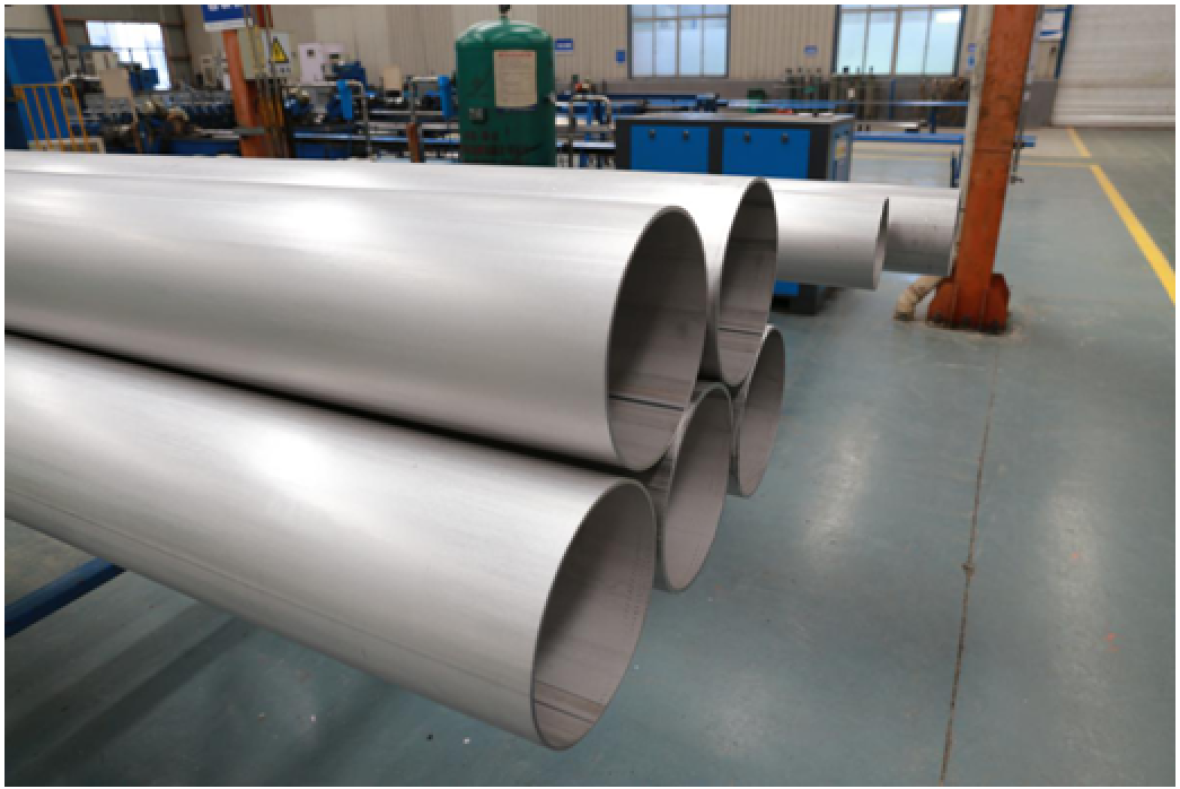

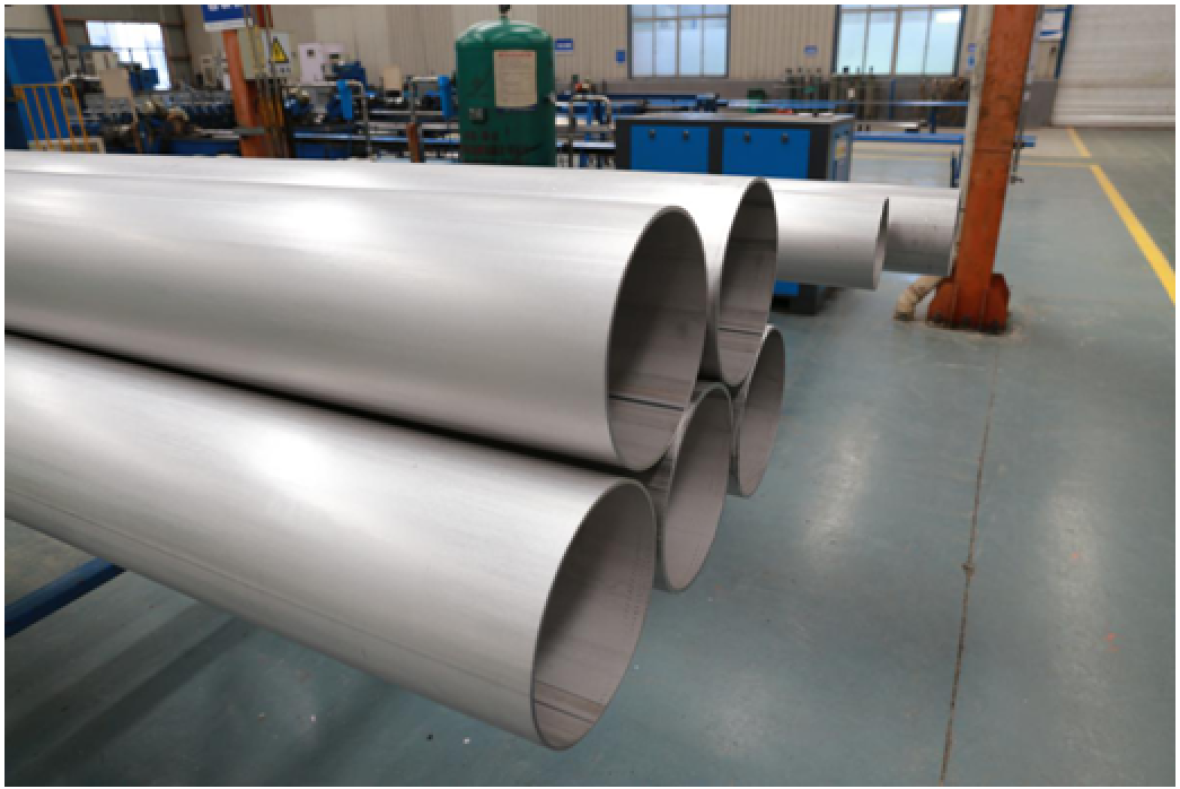

Stainless steel welded pipe is a kind of metal material widely used in industry, it has excellent mechanical properties and corrosion resistance, but in order to make it reach the best state, it needs to go through a special heat treatment process, that is, annealing treatment.

Annealing treatment is a method of improving the organisational structure and properties of stainless steel welded pipe by making the carbides and other phases in the stainless steel welded pipe dissolve in austenite through heating and rapid cooling. annealing solution treatment of stainless steel welded pipe can improve its tensile strength, elongation, hardness, corrosion resistance and other indicators to extend its service life.

Rotary induction annealing machine is a kind of equipment which converts electric energy into heat energy by using electromagnetic induction principle, it can heat up quickly, start and stop as you leave, save energy. The advantage of rotary induction annealing equipment is that it can be equipped with automatic pipe feeding and automatic pipe discharging device, adopting the rotary feeding method, which makes the pipe more uniformly heated and has better performance; the pipe will not be deformed after solid solution treatment, which saves the straightening process and improves the production efficiency.

So, how is the annealing treatment effect of rotary induction annealing equipment? These well-known enterprises are using this equipment, which fully demonstrates that the annealing solution treatment effect of rotary induction annealing equipment is very significant.

Guangdong Hangao Technology Co., Ltd

Recommended reading:Rotary solution production line

Recommended reading:Bright annealing production line for fine rolled pipe

Hotline:189-4243-7326